When it comes to achieving a smooth, polished finish on various materials, sandpaper plays a crucial role. Whether you’re a DIY enthusiast, a professional craftsman, or someone working on a home renovation project, understanding the different types of sandpaper and their specific uses can make all the difference in the quality of your work. At M/s Sandpaper Rodiez, we specialize in customizing abrasives to meet your unique needs, providing high-quality sandpaper imported from around the world and tailored to suit your specific requirements. In this comprehensive guide, we’ll delve into the different types of sandpaper, their uses, and how to select the right abrasive paper for your projects.

1. Introduction to Sandpaper and Abrasive Papers

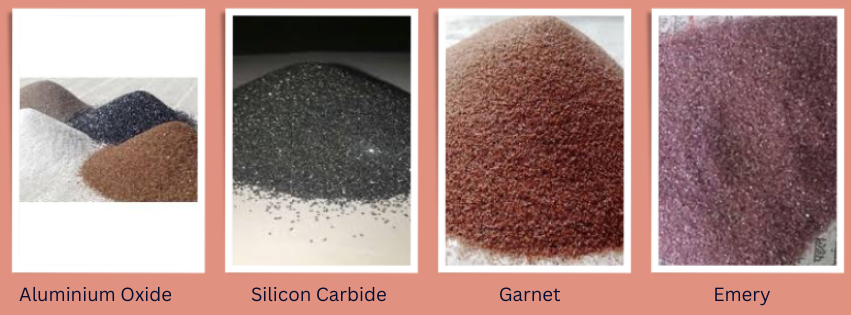

Sandpaper is a type of abrasive paper used for smoothing surfaces by rubbing them with an abrasive material. It consists of a backing material and an abrasive layer that is glued onto it. The abrasive layer is made up of materials like aluminum oxide, silicon carbide, garnet, or emery, each providing different levels of abrasiveness. Sandpaper comes in various forms and grades, making it versatile for a wide range of applications.

1.1 The Importance of Choosing the Right Sandpaper

Selecting the right sandpaper is essential for achieving the desired finish and avoiding damage to the material you are working on. Using the wrong type or grit of sandpaper can lead to poor results and increased labor. This guide will help you navigate the myriad options available and choose the best sandpaper for your specific needs.

2. Types of Sandpaper

Understanding the types of sandpaper available is the first step in mastering your sanding projects. Sandpaper can be categorized based on the abrasive material, the backing material, and the grit size.

2.1 Abrasive Materials

2.1.1 Aluminum Oxide

Aluminum oxide is one of the most common abrasive materials used in sandpaper. It is durable, long-lasting, and effective on both wood and metal surfaces. This type of sandpaper is ideal for general-purpose sanding and is often used in both woodworking and metalworking.

2.1.2 Silicon Carbide

Silicon carbide is a sharp, hard abrasive that provides a finer finish compared to aluminum oxide. It is suitable for use on harder materials such as glass, ceramics, and some metals. Silicon carbide sandpaper is often used for wet sanding applications because it performs well when used with water.

2.1.3 Garnet

Garnet sandpaper is known for its natural, sharp cutting action and is typically used for woodworking. It tends to break down faster than aluminum oxide or silicon carbide, so it is better suited for projects where a fine finish is desired over a long lifespan.

2.1.4 Emery

Emery sandpaper is used for heavy-duty tasks and is particularly effective for metalworking. It has a rough texture and is typically used for tasks that require significant material removal.

2.2 Backing Materials

2.2.1 Paper

Paper-backed sandpaper is commonly used in most sanding applications. It is flexible and easy to work with, making it suitable for both hand sanding and use with power sanders.

2.2.2 Cloth

Cloth-backed sandpaper, also known as sandpaper belts, is more durable than paper-backed varieties. It is often used for heavy-duty sanding and is ideal for use with belt sanders.

2.2.3 Sponge

Sponge-backed sandpaper provides extra flexibility and is ideal for sanding contours and irregular surfaces. It is often used in applications where a softer touch is needed, such as in automotive refinishing.

2.3 Grit Sizes

Grit size indicates the dimensions of the abrasive particles embedded in the sandpaper, which affects the sandpaper’s roughness or smoothness. Grit sizes are typically categorized into three main types:

2.3.1 Coarse Grit

Coarse grit sandpapers (ranging from 40 to 60 grit) are used for heavy material removal and rough shaping. They are ideal for initial sanding of rough surfaces or removing old finishes.

2.3.2 Medium Grit

Medium grit sandpapers (ranging from 80 to 120 grit) are used for smoothing surfaces after initial sanding. They are suitable for removing scratches left by coarse grit sandpaper and preparing the surface for finer sanding.

2.3.3 Fine Grit

Fine grit sandpapers (ranging from 150 to 220 grit and above) are used for final finishing and polishing. They are ideal for smoothing surfaces before applying finishes or paint.

3. Common Sandpaper Uses

Each type of sandpaper and grit size is suited for specific tasks. Here’s a look at how different sandpapers are used in various applications:

3.1 Woodworking

In woodworking, sandpaper is used to smooth rough surfaces, remove old finishes, and prepare wood for staining or painting. Coarse grit sandpaper is used for initial sanding to remove material quickly, while medium and fine grit sandpapers are used for achieving a smooth, polished finish.

3.2 Metalworking

For metalworking, sandpaper helps in removing rust, smoothing welds, and preparing metal surfaces for painting or plating. Emery and silicon carbide sandpapers are commonly used for these tasks due to their effectiveness on metal surfaces.

3.3 Automotive

In automotive work, sandpaper is used for bodywork, paint preparation, and finishing. Wet sanding with silicon carbide sandpaper is often employed to achieve a smooth surface before painting and polishing.

3.4 Drywall and Plaster

When working with drywall and plaster, sandpaper is used to smooth joints and seams. A fine-grit sandpaper is often used to achieve a smooth finish without damaging the surface.

4. How to Choose the Right Sandpaper

Selecting the right sandpaper involves considering several factors, including the material you’re working with, the type of finish you need, and the specific task at hand. Here are some tips for choosing the right sandpaper:

4.1 Identify the Material

Different materials require different types of sandpaper. For example, aluminum oxide sandpaper works well for general-purpose sanding on wood and metal, while silicon carbide is better suited for harder materials like glass and ceramics.

4.2 Determine the Task

The task you’re performing will influence the type of sandpaper you need. For heavy material removal, use coarse grit sandpaper, while fine grit is better for finishing and polishing.

4.3 Consider the Finish

If you’re preparing a surface for painting or staining, you may need to progress through different grits of sandpaper to achieve a smooth, even surface.

4.4 Evaluate Durability

Consider the durability of the sandpaper based on your project’s requirements. For heavy-duty tasks, cloth-backed sandpaper may be more suitable, while paper-backed sandpaper is sufficient for lighter tasks.

5. Tips for Effective Sanding

To get the best results from your sandpaper, follow these tips:

5.1 Sand with the Grain

When sanding wood, always sand with the grain to avoid scratches and achieve a smooth finish.

5.2 Use Proper Technique

Apply even pressure and avoid pressing too hard on the sandpaper. Let the abrasive material do the work for better results and longer-lasting sandpaper.

5.3 Keep Sandpaper Clean

Dust and debris can clog sandpaper, reducing its effectiveness. Clean the sandpaper regularly or replace it as needed to maintain optimal performance.

5.4 Progress Through Grit Sizes

For a smooth finish, progress through different grit sizes, starting with coarse grit and moving to finer grits.

6. Conclusion

Understanding the different types of sandpaper and their uses is essential for achieving the best results in your sanding projects. At M/s Sandpaper Rodiez, we are committed to providing high-quality, customized abrasives that meet your specific needs. Whether you’re working on woodworking, metalworking, automotive repairs, or any other project, selecting the right sandpaper can make a significant difference in the outcome.

For more information on our customized sandpaper solutions and how we can assist you in reaching your sanding goals, visit our website at Sandpaper Rodiez or contact us directly at our office located at Plot No 93, Main Chowk, Samaypur, Delhi – 110042. Let us help you find the perfect sandpaper for your next project and take your craftsmanship to the next level.