When it comes to achieving optimal results in any abrasive application, proper storage and maintenance of your abrasives are just as important as the quality of the abrasive material itself. Whether you are a seasoned professional or a DIY enthusiast, knowing how to store and maintain your abrasives can significantly extend their lifespan and ensure consistent performance. In this blog, we will explore the best practices for abrasive storage, the importance of abrasive maintenance, and tips for storing abrasives to help you get the most out of your investment.

The Importance of Proper Abrasive Storage

Abrasives, including sandpaper, grinding wheels, and other materials, are essential tools in various industries, from woodworking to metalworking. However, improper storage can lead to degradation, reducing the effectiveness of these tools and costing you time and money.

1. Preventing Moisture Damage

Excessive moisture poses a significant threat to the longevity and performance of abrasives. When abrasives are exposed to moisture, they can become clogged, lose their cutting ability, or even deteriorate completely. This is particularly true for sandpaper, which can warp or become unusable if not stored in a dry environment.

2. Avoiding Contamination

Contamination from dust, dirt, and other particles can reduce the efficiency of your abrasives. Storing abrasives in a clean, controlled environment helps prevent foreign materials from compromising their effectiveness.

3. Maintaining Adhesive Strength

For abrasives that rely on adhesives, such as sticky-backed sandpaper or discs, proper storage is crucial to maintain the adhesive strength. Exposure to heat or humidity can weaken the adhesive, making the abrasive difficult to use.

Best Practices for Abrasive Storage

Now that we understand why proper abrasive storage is important, let’s explore some best practices for storing your abrasives to ensure they remain in top condition.

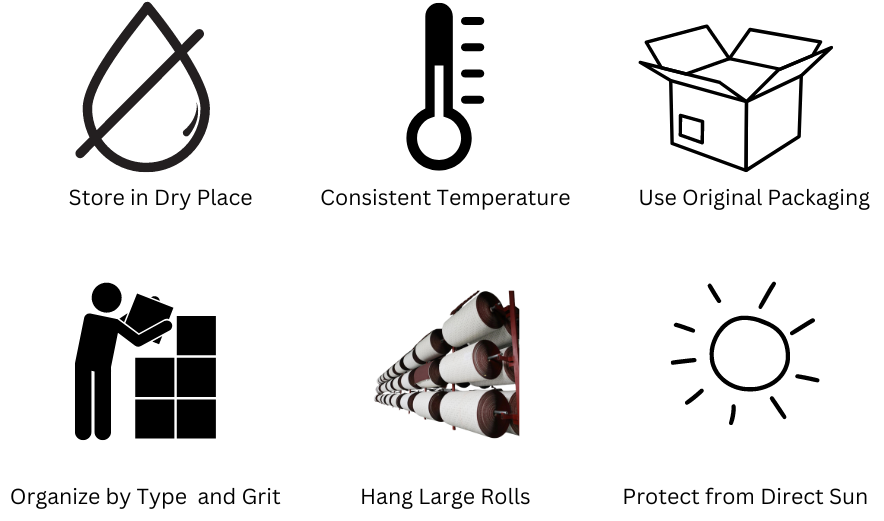

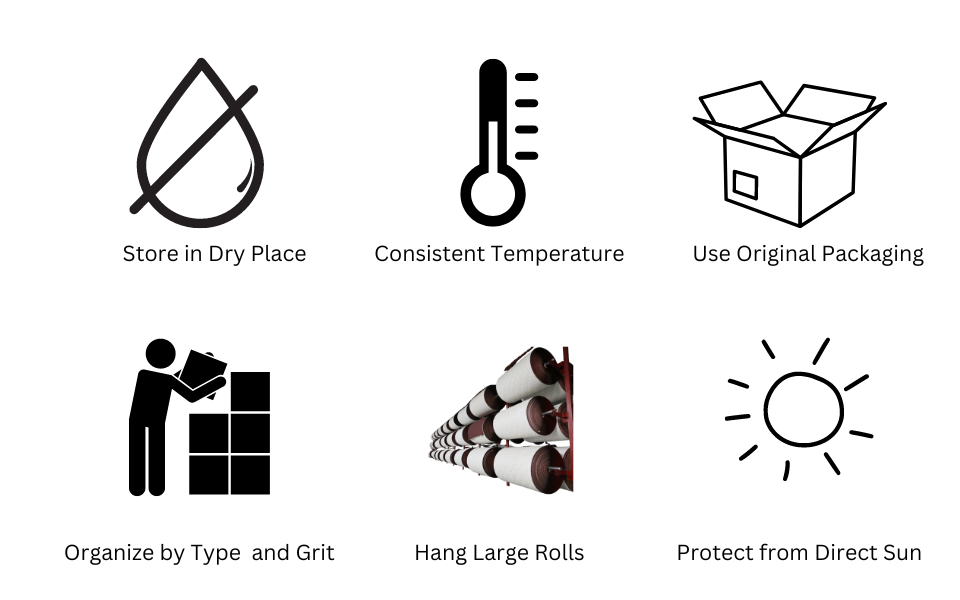

1. Keep Abrasives in a Dry Environment

The most critical factor in abrasive storage is keeping them dry. Store your abrasives in a location that is free from moisture, such as a sealed cabinet or storage container. For added protection, consider using silica gel packs or other desiccants to absorb any residual moisture.

2. Store at a Consistent Temperature

Temperature fluctuations can cause abrasives, especially those with adhesive backing, to deteriorate. Aim to store your abrasives in an environment with a consistent temperature, ideally between 15°C and 25°C (59°F and 77°F). Avoid storing abrasives in areas that are prone to extreme temperatures, such as garages or sheds.

3. Use Original Packaging

Whenever possible, store abrasives in their original packaging. Manufacturers often design packaging to protect the abrasives from environmental factors such as moisture and dust. If the original packaging is damaged, consider transferring the abrasives to a similar protective container.

4. Organize by Type and Grit

To prevent damage and make it easier to find the right abrasive for the job, store abrasives by type and grit. For example, keep all your sandpaper together and organize it by grit size. This not only protects the abrasives but also streamlines your workflow.

5. Hang Large Sheets or Rolls

For larger sheets or rolls of sandpaper, hanging them vertically can prevent curling and creasing. Use clamps or clips to hang the sheets in a dry, dust-free area. This method of storage also makes it easier to access the abrasives when needed.

6. Protect from Direct Sunlight

Direct sunlight can cause abrasives to degrade, especially those with adhesive backing. Store your abrasives in a shaded area or inside a cabinet to protect them from UV exposure.

Abrasive Maintenance: Ensuring Long-Lasting Performance

In addition to proper storage, regular maintenance of your abrasives is essential to ensure they perform at their best. Here are some key tips for abrasive maintenance:

1. Inspect Abrasives Before Use

Always examine abrasives for any signs of damage or wear before use to ensure optimal performance and safety. Look for tears, cracks, or any other irregularities that could affect performance. Using damaged abrasives can lead to subpar results and may even pose a safety risk.

2. Clean Abrasives After Use

After each use, clean your abrasives to remove any accumulated dust, debris, or residue. For sandpaper, a quick brush with a cleaning stick or rubber block can help remove debris. For grinding wheels, use a dressing tool to clean the surface and maintain sharpness.

3. Rotate Your Stock

Just like food, abrasives have a shelf life. To ensure you’re always using fresh abrasives, rotate your stock regularly. Use the oldest abrasives first and keep track of purchase dates to avoid using outdated materials.

4. Store Used Abrasives Separately

If you plan to reuse abrasives, store them separately from new ones to avoid confusion. Label the storage containers with the abrasive’s grit and condition to make it easier to find the right tool for the job.

5. Sharpen or Replace When Necessary

For tools like grinding wheels or sharpening stones, regular maintenance includes sharpening or dressing the abrasive surface. If an abrasive is no longer performing as it should, don’t hesitate to replace it. Using worn-out abrasives can lead to poor results and may damage the workpiece.

Common Mistakes to Avoid in Abrasive Storage and Maintenance

Even with the best intentions, it’s easy to make mistakes when it comes to storing and maintaining abrasives. Here are some common pitfalls to avoid:

1. Storing Abrasives in Humid Areas

As mentioned earlier, moisture is detrimental to abrasives. Avoid storing them in basements, garages, or other areas prone to humidity.

2. Mixing Different Types of Abrasives

Mixing different types of abrasives in the same storage container can lead to cross-contamination and damage. Always store different types of abrasives separately.

3. Ignoring Expiry Dates

While abrasives don’t technically expire, their effectiveness can diminish over time, especially if not stored properly. Pay attention to the condition of your abrasives and don’t hesitate to replace them if they’re no longer performing well.

4. Using Damaged Abrasives

It can be tempting to use an abrasive that has only a small tear or imperfection, but doing so can compromise your work and safety. Always use abrasives in good condition.

How Sandpaper Rodiez Ensures Quality in Abrasives

At M/s Sandpaper Rodiez, we understand the importance of quality when it comes to abrasives. That’s why we source the best sandpaper from around the world and customize it to meet our clients’ specific needs. Our abrasives are designed to perform consistently, and with proper storage and maintenance, they will serve you well for a long time.

We provide detailed guidance on abrasive storage and maintenance to all our clients, ensuring they get the most out of their investment. Whether you’re a professional contractor or a hobbyist, our team is here to help you choose the right abrasives and maintain them properly.

Conclusion

Proper storage and maintenance of your abrasives are crucial to achieving the best results in your work. By following the tips and best practices outlined in this guide, you can extend the life of your abrasives and ensure they perform at their best. Remember, the key to effective abrasive storage is keeping them dry, organized, and protected from environmental factors.

At Sandpaper Rodiez, we are committed to providing top-quality abrasives and expert advice to help you get the most out of your tools. Whether you’re working on a small DIY project or a large industrial application, we have the right abrasives and the knowledge to help you succeed.

For more information on our products and services, visit our website at Sandpaper Rodiez or contact us directly. Let us help you achieve excellence in your work with the best abrasives and the right maintenance practices.