In the world of industrial manufacturing and construction, the role of abrasives is crucial. From shaping materials to polishing surfaces, abrasives are an integral part of various industrial processes. M/s Sandpaper Rodiez is proud to offer top-notch abrasives that meet the specific needs of our clients. Here, we explore the top 10 high-quality abrasives that can enhance the efficiency and quality of your industrial operations.

1. Aluminum Oxide Abrasives

Overview:

Aluminum oxide is one of the most popular industrial abrasives due to its versatility and durability. It’s used in various forms, such as sandpaper, grinding wheels, and blasting media.

Key Features:

- High hardness and toughness

- Ideal for ferrous metals, hardwood, and other materials

- Available in different grit sizes

Applications:

Aluminum oxide is widely used in metalworking, woodworking, and for general-purpose sanding.

Why Choose Aluminum Oxide:

Its ability to provide consistent cutting action and its longevity make it a go-to choice for many industries.

2. Silicon Carbide Abrasives

Overview:

Silicon carbide is a man-made abrasive renowned for its exceptional hardness and sharp, aggressive cutting action. It’s often used where a more aggressive cutting action is required.

Key Features:

- Very hard and brittle

- Suitable for non-ferrous metals, stone, and glass

- Effective in wet or dry sanding

Applications:

Ideal for finishing hard surfaces and grinding tough materials like ceramics and non-ferrous metals.

Why Choose Silicon Carbide:

If you need an abrasive that can cut through hard materials with precision, silicon carbide is the best choice.

3. Ceramic Alumina Abrasives

Overview:

Ceramic alumina abrasives are known for their exceptional durability and performance. They are engineered for heavy-duty grinding and offer a longer lifespan compared to other abrasives.

Key Features:

- Extremely hard and sharp

- Self-sharpening properties

- Provides cooler cutting action

Applications:

Perfect for high-pressure applications, especially in the aerospace and automotive industries.

Why Choose Ceramic Alumina:

The self-sharpening quality ensures that it retains its cutting ability over time, making it a cost-effective option for tough jobs.

4. Garnet Abrasives

Overview:

Garnet is a natural mineral abrasive that is highly valued for its environmental friendliness and non-toxic nature. It’s widely used in waterjet cutting and sandblasting.

Key Features:

- High hardness and strength

- Environmentally safe and recyclable

- Low dust generation

Applications:

Ideal for sandblasting, waterjet cutting, and surface preparation.

Why Choose Garnet:

For industries that prioritize sustainability, garnet abrasives provide an effective and eco-friendly solution.

5. Zirconia Alumina Abrasives

Overview:

Zirconia alumina is a durable synthetic abrasive known for its toughness and resistance to heat. It’s used in high-pressure grinding and cutting applications.

Key Features:

- Extremely durable and long-lasting

- Suitable for high-pressure applications

- High resistance to heat

Applications:

Commonly used in metal fabrication, especially for grinding steel and other metals.

Why Choose Zirconia Alumina:

If your application involves high-pressure grinding, zirconia alumina provides the toughness and longevity needed for demanding tasks.

6. Diamond Abrasives

Overview:

Diamond abrasives are the hardest known abrasives, offering unparalleled cutting efficiency and precision. They are ideal for cutting and grinding the hardest materials.

Key Features:

- Extremely hard and wear-resistant

- Provides precise cutting and shaping

- Ideal for high-precision applications

Applications:

Used in industries like electronics, automotive, and construction for cutting, grinding, and polishing hard materials like glass, ceramics, and stone.

Why Choose Diamond Abrasives:

For applications that require cutting-edge precision and durability, diamond abrasives are the ultimate choice.

7. Cubic Boron Nitride (CBN) Abrasives

Overview:

CBN is a synthetic abrasive almost as hard as diamond, used mainly for machining hard metals like tool steel.

Key Features:

- Extremely hard and durable

- Provides consistent performance at high temperatures

- Ideal for grinding ferrous metals

Applications:

Widely used in metalworking, particularly for grinding hardened steel.

Why Choose CBN Abrasives:

For high-temperature applications where other abrasives might fail, CBN provides reliable performance and longevity.

8. Emery Abrasives

Overview:

Emery is a natural abrasive known for its fine grain and polishing capabilities. It is commonly used in hand tools and coated abrasives.

Key Features:

- Fine grain texture

- Suitable for polishing and light grinding

- Versatile and cost-effective

Applications:

Ideal for polishing metals, stones, and glass.

Why Choose Emery Abrasives:

For finishing tasks that require a smooth, polished surface, emery provides an excellent balance between effectiveness and cost.

9. Pumice Abrasives

Overview:

Pumice is a natural volcanic abrasive known for its gentle yet effective abrasive qualities. It’s often used in applications requiring a light touch.

Key Features:

- Lightweight and porous

- Ideal for gentle polishing and cleaning

- Non-toxic and eco-friendly

Applications:

Commonly used in the wood, glass, and cosmetic industries for light sanding and finishing.

Why Choose Pumice Abrasives:

For delicate applications that require a gentle abrasive, pumice offers a natural and environmentally friendly option.

10. Steel Grit Abrasives

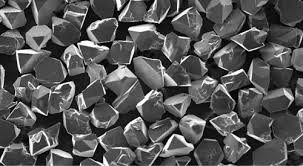

Overview:

Steel grit is a tough, angular abrasive made from crushed steel, used primarily in surface preparation and cleaning.

Key Features:

- Highly durable and reusable

- Aggressive cleaning action

- Ideal for surface preparation before coating

Applications:

Used in industries like shipbuilding, automotive, and construction for surface cleaning and preparation.

Why Choose Steel Grit Abrasives:

For heavy-duty surface preparation tasks, steel grit provides the toughness and efficiency needed to get the job done.

Conclusion

Choosing the right abrasive for your industrial application is crucial for achieving the best results. M/s Sandpaper Rodiez specializes in providing high-quality abrasives tailored to meet the specific needs of our clients. Whether you need the toughness of aluminum oxide, the precision of diamond, or the eco-friendliness of garnet, we have the right solution for you.

Explore our extensive range of industrial abrasives on our website and contact us to find the perfect abrasive for your application. With our expertise and commitment to quality, we ensure that your industrial processes are efficient, precise, and cost-effective